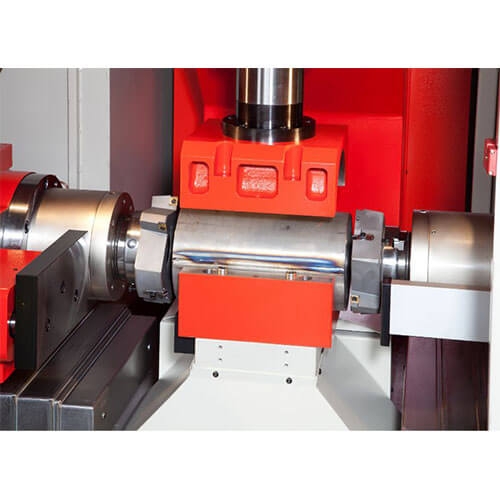

| Horizontal Milling Machine |

| MODEL NO. |

NC-400i |

| Machining capacity |

Length of workpiece |

50 ~ 350 mm |

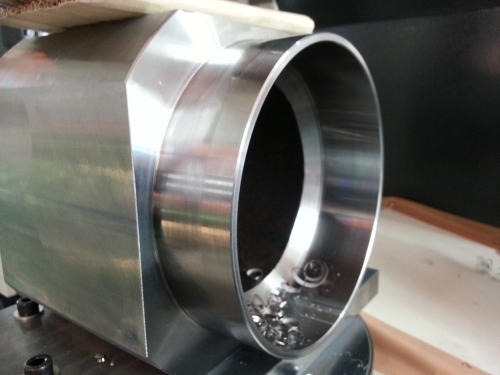

| Max. thickness of round tube |

3.2 ~ 6 mm |

| Diameter of round tube |

ф50 ~ 180 mm |

| Travel & table |

Travel of table Z-axis |

600 mm |

| Travel of head X/Y-axis |

180 mm |

| Feed speed |

Rapid feed speed Z-axis |

15 m/min |

| Rapid feed speed X/Y-axis |

15 m/min |

| Cutting feed speed manual |

1 – 1500 mm/min |

| Spindle |

Spindle |

NT50 equivalent |

| Dimension of spindle nose |

ф 40 mm |

| Spindle speed |

200 ~ 1600 RPM |

| Vertical clamping |

Vertical clamp hydraulic cylinder |

ф 50 x 250 mm |

| Motor |

Spindle motor output |

11 kW |

| Feed motor X,Y,Z-axis |

1.5 kW |

| Control system |

MITSUBISHI |

| Others |

Voltage |

220 V (Transformer) |

| Machine weight |

5 tons |

| Machine size W x L x H (mm) |

2500 x 2600 x 2300 |