| Cutting capacity |

No. of control spindle |

4 |

| Cutting size Min. /Max. |

500 / 1000 mm |

| Max. cutting thickness (Cutter) |

425 mm |

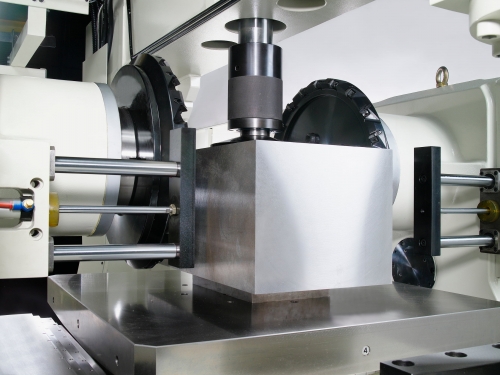

| Spindle box & spindle |

Distance between spindle nose |

600 ~ 1200 mm |

| Spindle motor |

30 HP or 35HP (22/26 kw) |

| Spindle taper |

NT – 60 |

| Spindle speed variable speed |

50 ~ 300 rpm |

Z-axis(Longitudinal)

X-axis(Right spindle)

Y-axis(Left spindle)

A-axis(Rotator) |

Max. longitudinal travel (Z-axis) |

2250 mm |

| Max. spindle travel (X,Y-axes) |

385 mm |

| Servo motor (Z, A-axes) |

4 kw |

| Servo motor (X, Y-axes) |

3 kw |

| Dia. of ball screw (Z-axis) |

Φ63 P 12 |

| Dia. of ball screw (X, Y-axis) |

Φ50 P10 |

| Rapid feed (Z-axis) |

6 m/min |

| Rapid feed (X, Y-axis) |

6 m/min |

| Work table |

Worktable area (mm) |

920 x 2300 |

| Index table |

Dimensions (mm) |

800 x 800 |

| Max. load |

4000 kg |

| Oil tank capacity |

Hydraulic unit |

100L |

| Lubrication oil tank |

2L x 3 |

| Others |

Machine dimension W x L x H (mm) |

4100x 6500 x 2550 |

| N.W. |

17.5 tons |